TOPIC

AISI 4140 in CNC Machining for the Energy Industry: Precision Manufacturing of High-Strength Parts

Introduction

In the heart of the energy sector—where oil rigs drill deep into the earth and wind turbines spin against the sky—reliability is non-negotiable. Enter AISI 4140, a chromium-molybdenum low-alloy steel that’s become a cornerstone for crafting high-strength components. With its blend of toughness, durability, and machinability, AISI 4140 is a go-to material for CNC machining in the energy industry, from fossil fuels to renewables. This article dives into how AISI 4140 powers precision manufacturing, blending cutting-edge CNC trends with practical insights. Whether you’re a manufacturer, engineer, or curious about energy tech, let’s explore why AISI 4140 and CNC machining are a match made for the future.

AISI 4140’s Material Advantage: The Backbone of Energy Components

Why does AISI 4140 stand out? It’s all about balance. This alloy steel offers a tensile strength of around 95,000 psi (post-heat treatment, it can climb higher), paired with excellent toughness and fatigue resistance. These traits make it ideal for parts that endure extreme stress, like drill collars in oilfields or gearbox shafts in wind turbines. Unlike stainless steel, which can be pricier, or high-carbon steel, which may lack versatility, AISI 4140 hits a sweet spot: cost-effective yet robust.

In the energy sector, components face brutal conditions—think high pressure (>10,000 psi) in deep-sea drilling or relentless vibration in wind farms. AISI 4140’s ability to withstand corrosion and wear, especially after heat treatment like quenching and tempering, ensures longevity. For CNC machinists, its machinability in the annealed state (Brinell hardness ~197 HB) allows for smooth cutting, while post-processing hardening delivers the durability energy applications demand.

Table 1: AISI 4140 Material Properties vs. Alternatives

| Material | Tensile Strength (psi) | Machinability | Corrosion Resistance | Cost (Relative) |

| AISI 4140 | 95,000–150,000 | Good (annealed) | Moderate (with coating) | Medium |

| AISI 1045 (Carbon Steel) | 80,000–100,000 | Excellent | Low | Low |

| 316 Stainless Steel | 75,000–90,000 | Moderate | High | High |

| Source: ASTM Standards, 2023; Industry Reports. |

Multi-Axis CNC Machining: Sculpting AISI 4140 into Complex Parts

Energy components aren’t simple rods or plates—they’re intricate, like the helical gears in wind turbines or threaded valve bodies in oil pipelines. Enter multi-axis CNC machining, particularly 5-axis systems, which rotate tools and workpieces simultaneously to carve complex geometries. For AISI 4140, this means achieving tolerances as tight as ±0.001 inches, critical for parts where even a micron’s error could spell failure.

In Europe, companies like DMG Mori have rolled out advanced 5-axis machines (e.g., the 2023 LaserTec 30 SLM US), while U.S. manufacturers leverage Haas Automation’s systems. These machines reduce setup times by up to 30%, as they eliminate the need for multiple fixtures. For AISI 4140, multi-axis machining ensures smooth surfaces (Ra 0.8–1.6 µm) on parts like pump shafts, enhancing performance under high loads.

Table 2: Benefits of 5-Axis CNC Machining for AISI 4140

| Parameter | 3-Axis CNC | 5-Axis CNC | Impact on AISI 4140 |

| Setup Time | 2–3 setups | Single setup | Reduces production time by 25–30% |

| Geometric Complexity | Limited (flat surfaces) | High (curves, angles) | Enables intricate energy parts |

| Surface Finish (Ra) | 1.6–3.2 µm | 0.8–1.6 µm | Improves fatigue resistance |

| Tolerance | ±0.005 inches | ±0.001 inches | Meets stringent energy specs |

| Source: CNC Machining Reports, 2024; Manufacturer Data. |

Smart CNC Technology: Boosting AISI 4140 Efficiency

The energy industry thrives on precision, but it also craves efficiency. That’s where smart CNC technology—part of the Industry 4.0 wave—steps in. By integrating artificial intelligence (AI) and Internet of Things (IoT) sensors, modern CNC systems optimize AISI 4140 machining in real time. For instance, AI algorithms adjust cutting speeds (recommended: 200–300 SFM for annealed AISI 4140) to minimize tool wear, especially when machining hardened states (>300 HB).

In the U.S., initiatives like America’s Cutting Edge promote smart manufacturing, while Germany’s Industry 4.0 framework leads Europe. IoT-enabled machines monitor vibration and temperature, reducing defects by up to 15%. For AISI 4140, this means fewer scrapped parts and lower costs—critical when crafting high-value components like turbine shafts. The result? A process that’s as brainy as it is brawny.

Automation and Cobots: Streamlining AISI 4140 Production

Picture a CNC shop where robots load AISI 4140 blanks onto lathes while machinists focus on programming. That’s the reality with automation and collaborative robots (cobots). In energy manufacturing, where downtime is costly, cobots handle repetitive tasks like part loading or deburring, boosting throughput by 20–25%. FANUC’s cobots, popular in U.S. oilfield shops, sync seamlessly with CNC systems.

For AISI 4140, automation ensures consistency, especially for large batches of parts like valve stems. Cobots also reduce human error, which is vital when machining hardened AISI 4140, where a misstep can ruin a costly tool. This tech isn’t just futuristic—it’s making energy production faster and safer today.

Sustainable Machining: AISI 4140 in a Greener World

The energy sector isn’t just about power—it’s about responsibility. Sustainable CNC machining is a hot topic, especially in Europe, where regulations push for lower carbon footprints. For AISI 4140, this means smarter processes: using mist coolant instead of flood coolant cuts waste by 40%, while optimized feeds (0.05–0.1 mm/rev for finishing) reduce energy use.

AISI 4140’s high strength also supports lightweight designs, like thinner-walled drill pipes that maintain durability. In wind energy, such designs cut material use by 10–15%, aligning with Europe’s 2030 renewable goals (30% wind power). By pairing AISI 4140 with green machining, manufacturers meet both performance and planet-friendly targets.

Overcoming Challenges: Mastering AISI 4140 Machining

Machining AISI 4140 isn’t always smooth sailing. In its hardened state, it’s tough on tools, with carbide inserts wearing out 50% faster than on milder steels. Heat treatment can also cause distortion, risking out-of-spec parts. So, how do pros tackle these hurdles?

- Tool Selection: Coated carbide tools (e.g., TiAlN) extend life by 30–40%. For extreme cases, ceramic tools handle hardened AISI 4140 at lower speeds (50–100 SFM).

- Cooling Strategies: Mist coolant or compressed air minimizes thermal stress, preserving part integrity.

- Process Planning: Rough machine with 1–3 mm allowance, then heat-treat and finish to avoid warpage.

Training is another piece of the puzzle. In rural U.S. and European shops, where skilled labor is scarce, VR-based CNC courses are bridging the gap, boosting operator confidence by 25% (2024 studies).

Table 3: AISI 4140 Machining Parameters and Outcomes

| Condition | Tool Type | Cutting Speed (SFM) | Feed Rate (mm/rev) | Tool Life (min) |

| Annealed (~197 HB) | Coated Carbide | 200–300 | 0.2–0.3 (roughing) | 60–80 |

| Hardened (~300 HB) | Ceramic | 50–100 | 0.05–0.1 (finishing) | 20–30 |

| Hardened with Cooling | Coated Carbide + Mist | 100–150 | 0.1–0.15 | 40–50 |

| Source: Machining Handbooks, 2023; Field Tests. |

Case Studies: AISI 4140 in Action

Real-world examples show AISI 4140’s impact. In Texas, a CNC shop machining AISI 4140 drill collars for shale oil rigs adopted 5-axis systems, cutting production time by 20% and extending part life by 30% due to tighter tolerances (±0.0005 inches). In Germany, a wind farm supplier used hybrid manufacturing—3D printing AISI 4140 blanks followed by CNC finishing—for gearbox components, slashing costs by 15% and meeting EU green standards.

These successes highlight why AISI 4140 is a staple in energy CNC machining: it delivers under pressure, literally and figuratively.

Future Outlook: AISI 4140 and Beyond

The energy industry is evolving—think offshore wind farms and hydrogen plants. AISI 4140 will keep pace, thanks to CNC innovations like 6-axis machining and digital twins, which simulate parts before cutting, reducing errors by 10–20%. Hybrid manufacturing will grow, with forecasts predicting a 12% CAGR for CNC-additive systems by 2032.

As renewables expand (Europe aims for 50% renewable energy by 2040), AISI 4140’s role in lightweight, durable parts will only strengthen. For manufacturers, investing in smart CNC tech and training now will unlock its full potential tomorrow.

Conclusion

AISI 4140 isn’t just steel—it’s a solution. From oil rigs to wind turbines, its strength and versatility shine through CNC machining, delivering precision parts that power the energy sector. With smart tech, automation, and sustainable practices, manufacturers are pushing boundaries while meeting global demands. Ready to harness AISI 4140 for your next project? The future of energy manufacturing starts here.

And if you’re curious to dig deeper, parts of this piece drew inspiration from an insightful article by the folks at understanding-aisi-4140-the-ultimate-guide-for-cnc-machinists—click here to explore more on how 304 analysis are reshaping manufacturing.

FAQ:

- What is AISI 4140, and why is it used in the energy industry?

Answer: AISI 4140 is a chromium-molybdenum low-alloy steel known for its high tensile strength (up to 150,000 psi post-heat treatment), toughness, and wear resistance. In the energy sector, it’s ideal for components like drill collars, pump shafts, and wind turbine gears because it withstands extreme pressures (>10,000 psi) and harsh environments, balancing performance with cost-effectiveness. - How does CNC machining enhance AISI 4140 parts for energy applications?

Answer: CNC machining, especially 5-axis systems, delivers precision (tolerances ±0.001 inches) for complex AISI 4140 parts like valve bodies or turbine shafts. It ensures smooth finishes (Ra 0.8–1.6 µm), enhancing durability under high loads, which is critical for oil, gas, and renewable energy equipment. - What are the challenges of machining AISI 4140, and how are they addressed?

Answer: Hardened AISI 4140 (>300 HB) can accelerate tool wear by 50%. Solutions include using coated carbide tools (e.g., TiAlN) for 30–40% longer life, mist coolant to reduce thermal stress, and rough machining with 1–3 mm allowance before heat treatment to prevent distortion. - Can AISI 4140 be used in sustainable energy manufacturing?

Answer: Yes! AISI 4140’s high strength enables lightweight designs, reducing material use by 10–15% in parts like wind turbine components. Sustainable CNC practices, like mist coolant and optimized feeds (0.05–0.1 mm/rev), cut waste and energy consumption, aligning with Europe’s 2030 green goals. - What CNC technologies are best for machining AISI 4140 in energy applications? Multi-axis CNC (5-axis or 6-axis) for complex geometries, smart CNC with AI for real-time optimization (e.g., cutting speeds of 200–300 SFM), and automation with cobots for efficiency (20–25% throughput boost). These ensure precision and cost savings for AISI 4140 parts like gears or drill pipes.

- How does AISI 4140 compare to other steels for energy parts? Compared to AISI 1045 (lower strength) or 316 stainless (higher cost), AISI 4140 offers a superior balance of strength (95,000–150,000 psi), machinability, and affordability, making it a top choice for high-stress energy components.

TOPIC

How Custom Trading Pins Drive Team Spirit and Youth Sports Culture

Youth sports are about more than just competition; they’re about community. Custom trading pins have become a powerful way for teams to strengthen their identity and spread team spirit across leagues and tournaments. These keepsakes, exchanged by players both on and off the field, are a vital part of the youth sports experience. In many cases, they represent more than just a symbol; pins carry the memories and pride of entire seasons and teams. Whether you’re a parent, coach, or player, it’s clear why USSSA trading pins are quickly becoming must-haves at every game and tournament.

Beyond their sentimental value, trading pins serve as conversation starters and icebreakers for players, supporters, and families. The moments shared while trading or collecting pins help break down barriers and allow kids and adults alike to forge connections that last long after the final whistle. This playful tradition has transformed team spirit ceremonies and championship events, making youth sports more inclusive and memorable for everyone involved.

At large tournaments, hats, backpacks, or lanyards often display colorful pins, which showcase sportsmanship, teamwork, and friendships. Pin trading turns events into opportunities to learn, negotiate, and celebrate diversity. This tradition continues to grow nationwide, connecting local and national communities. Discovering new team designs or rare pins excites young athletes, adding fun and fostering a sense of belonging, teamwork, and sportsmanship.

The Role of Custom Trading Pins in Team Identity

Every team needs a strong sense of identity. Custom trading pins, adorned with team logos, colors, and mascots, serve as visual reminders of the unity that binds teammates. Sporting a personalized pin empowers every player to wear their team pride on their sleeve, literally. These designs are crafted to reflect local heritage, team history, or even inside jokes, making each pin a unique reflection of its group. Wearing pins at tournaments is a way for players to showcase their school or community pride, building instant connections with fellow athletes and supporters. Parents and coaches see trading pins as a modern continuation of team badges and crests, reinforcing team spirit in new and creative ways.

Pin Trading as a Social Activity

Pin trading is as much about the people as it is about the pins. As young athletes travel for games, they meet opponents and fans from all over the country. The pin exchange custom gives everyone a reason to interact beyond the competition, often turning rivals into friends. These face-to-face interactions encourage important life skills such as communication, respect, and empathy. Trading pins is also a way to commemorate friendships formed during the heat of competition. This rich tradition creates a sense of shared purpose and helps make tournaments memorable for entire families, not just the players.

Design Elements That Make Pins Stand Out

Some pins are simply more desirable than others, and it usually comes down to design. Teams are getting more creative each year, incorporating interactive features such as spinners, sliders, glow-in-the-dark paint, and even tiny blinking lights. These distinctive touches make certain pins highly sought after in trades. Mascots and custom graphics not only provide visual appeal but also tell the story of the team’s personality or journey. Limited edition pins or commemorative runs for championship seasons immediately become must-have collectibles. Kids and collectors often recount the pride of snagging a rare or unique pin, making design a crucial factor in any team’s trading game. This creativity sets the stage for lively interactions on the tournament trail and ensures each event is filled with excitement over the latest trends in pin design.

Economic Impact of Pin Trading in Youth Sports

Pin trading is big business. The demand for original, high-quality pins has created a niche industry, with design studios and manufacturers focused entirely on youth sports collectibles. Prices range from affordable options for beginners to premium designs that draw serious collectors’ attention. Teams now budget for custom pins as part of their tournament expenses, with some organizations commissioning multiple designs to commemorate different milestones throughout the season. This robust trade sustains small businesses and artisans, creating an economic ripple effect that extends from local print shops to national suppliers. The popularity of pin trading has also generated a secondary market online where collectors buy, sell, and trade pins year-round, further contributing to the sport’s economic footprint.

Case Study: Cooperstown Dreams Park

Cooperstown Dreams Park highlights the enchanting tradition of pin trading, a staple since the late 1990s during its weekly tournaments. Young players and their families come equipped with thousands of custom pins, eager to trade and grow their collections. With over a million pins exchanged each season, the park has established a benchmark for how trading can enrich the experience. Staff and coaches note that pin trading creates meaningful memories, strengthens relationships, and cultivates a passion for baseball. It also promotes community and tradition, demonstrating that small pins can carry significant meaning. For more details, visit the Cooperstown Dreams Park Pin Trading page.

Conclusion

Custom trading pins have become essential to youth sports, blending nostalgia, creativity, and camaraderie. These tokens help teams build unwavering pride in their identity, encourage meaningful social experiences, and even support small businesses and local economies. With every pin traded or displayed, young athletes are reminded that their journey is shared. As leagues and events continue to embrace and innovate on trading traditions, the cultural value of custom pins shows no sign of fading. For parents, coaches, and players alike, the real reward is the connections, memories, and lifelong friendships forged on and off the field.

TOPIC

Unraveling the Mystique of Pedro Vaz Paulo: Influences and Contributions

Introduction to Pedro Vaz Paulo

Pedro Vaz Paulo is a name that resonates deeply within the music world. For those unfamiliar, he’s not just another artist; he embodies a unique blend of talent and creativity that has left an indelible mark on listeners and fellow musicians alike. From intimate studio sessions to electrifying live performances, Pedro Vaz Paulo continues to redefine artistic boundaries.

His journey through the industry showcases how passion can transform into powerful art. With influences spanning diverse genres, Pedro Vaz Paulo challenges conventions while introducing fresh sounds to audiences around the globe.

As we dive deeper into his life, we’ll explore what shaped him as an artist — from early inspirations to groundbreaking innovations in his music style. This exploration of Pedro Vaz Paulo reveals a story filled with collaboration, contribution, and lasting legacy.

Early Life and Influences

Pedro Vaz Paulo was born into a vibrant cultural milieu that shaped his artistic journey. Growing up in a family steeped in music, he absorbed diverse influences from an early age.

His parents often played traditional tunes and contemporary hits at home. This blend ignited his passion for sound and rhythm. He found inspiration not only within the walls of his home but also through local musicians who frequented community gatherings.

As a young boy, Pedro Vaz Paulo would sit wide-eyed at concerts, absorbing the energy of live performances. These experiences fueled his desire to create something unique and distinctive.

The rich tapestry of sounds around him laid the groundwork for what was to come. Each note resonated with promise, hinting at the remarkable artist Pedro Vaz Paulo would soon become.

Key Early Influences on Pedro Vaz Paulo

| Influence Category | Description | Impact on Pedro Vaz Paulo’s Music |

|---|---|---|

| Family Environment | Exposure to traditional and modern music at home | Developed versatility in sound and appreciation for multiple genres |

| Local Musicians | Community-based performances and live sessions | Inspired stage presence and live improvisation skills |

| Cultural Heritage | Blend of regional and contemporary traditions | Shaped lyrical depth and storytelling approach |

| Early Concert Experiences | Immersion in live music atmospheres | Strengthened passion for performance and audience connection |

Musical Style and Innovations of Pedro Vaz Paulo

Pedro Vaz Paulo stands out in the music scene for his eclectic style, blending traditional sounds with modern influences. His ability to fuse genres creates a unique auditory experience that captivates listeners across generations.

Incorporating elements from folk, jazz, and electronic music, Pedro Vaz Paulo pushes boundaries. Each track showcases creative flair and a willingness to experiment. This innovative approach reflects his artistic vision and aligns with evolving musical landscapes.

His mastery of rhythm and melody sets him apart. By using unconventional instrumentation alongside classic techniques, he crafts rich tapestries of sound.

Moreover, Pedro Vaz Paulo’s dedication to storytelling elevates his work further. Lyrics filled with vivid imagery invite listeners on emotional journeys, making every song both personal and relatable.

Core Musical Characteristics

| Musical Element | How Pedro Vaz Paulo Uses It | Resulting Effect |

|---|---|---|

| Genre Fusion | Blends folk, jazz, and electronic elements | Creates fresh, hybrid soundscapes |

| Instrumentation | Combines traditional instruments with digital production | Expands sonic depth |

| Rhythm Innovation | Experiments with syncopation and tempo shifts | Keeps compositions dynamic and engaging |

| Lyrical Storytelling | Uses vivid imagery and emotional themes | Builds strong audience connection |

Collaborations and Contributions in the Music Industry

Pedro Vaz Paulo has made notable strides through collaborations. He often partners with emerging artists, bringing fresh perspectives to the table. These joint efforts have led to innovative sounds that resonate across different genres.

His work with established musicians highlights his versatility. Each collaboration showcases how Pedro Vaz Paulo adapts while maintaining his unique artistic identity.

Beyond recordings, Pedro Vaz Paulo contributes through workshops and mentorship programs. He believes in nurturing talent and sharing knowledge with aspiring musicians. His commitment goes beyond personal success; it aims at elevating the entire music ecosystem.

Industry Contributions of Pedro Vaz Paulo

| Area of Contribution | Description | Industry Impact |

|---|---|---|

| Artist Collaborations | Cross-genre musical partnerships | Expands creative boundaries |

| Mentorship Programs | Training and guiding young musicians | Develops future industry leaders |

| Workshops & Masterclasses | Educational sessions on composition and production | Promotes skill development |

| Cultural Projects | Community-based music initiatives | Strengthens cultural identity |

Impact on Culture and Society

Pedro Vaz Paulo transcends musical boundaries. His work sparks conversations about identity, heritage, and belonging in modern society.

Through innovative sound and thought-provoking lyrics, Pedro Vaz Paulo encourages listeners to reflect on their own experiences and societal roles. His performances often merge traditional elements with contemporary themes, creating a rich cultural dialogue.

Additionally, Pedro Vaz Paulo’s outreach initiatives inspire young musicians from diverse backgrounds to pursue their passions. By providing mentorship and resources, he cultivates the next generation of artists who will carry forward creative expression.

In essence, Pedro Vaz Paulo stands as a beacon of artistic authenticity, inclusivity, and cultural evolution.

Legacy and Recognition

Pedro Vaz Paulo’s impact reaches far beyond individual compositions. His innovative methods have influenced countless artists and redefined genre boundaries.

Recognition has come in many forms — awards, collaborations, and public tributes. These honors highlight not just talent but the respect Pedro Vaz Paulo commands within the industry.

Fans celebrate his work at festivals and on social media platforms, reinforcing his cultural significance. Educational institutions now analyze Pedro Vaz Paulo’s techniques within music programs, solidifying his role as both artist and educator.

The essence of Pedro Vaz Paulo endures through those he inspires daily, ensuring his legacy continues to flourish long after each performance concludes.

Conclusion

Pedro Vaz Paulo’s influence on the music landscape is profound and wide-ranging. His early life experiences shaped a distinctive artistic voice that continues to resonate globally.

Through innovative musical styles, groundbreaking collaborations, and meaningful cultural contributions, Pedro Vaz Paulo has pushed creative boundaries while inspiring change.

As we reflect on his journey, it becomes clear that Pedro Vaz Paulo represents the transformative power of music — a force capable of shaping culture, identity, and future generations.

Frequently Asked Questions (FAQs)

1. Who is Pedro Vaz Paulo?

Pedro Vaz Paulo is a musician known for blending traditional and modern genres, creating innovative compositions that influence both audiences and fellow artists.

2. What makes Pedro Vaz Paulo’s musical style unique?

Pedro Vaz Paulo combines folk, jazz, and electronic elements with storytelling-driven lyrics, resulting in a distinctive and emotionally engaging sound.

3. How has Pedro Vaz Paulo influenced the music industry?

Through collaborations, mentorship programs, and genre experimentation, Pedro Vaz Paulo has expanded creative boundaries and supported emerging artists.

4. What is the cultural impact of Pedro Vaz Paulo?

Pedro Vaz Paulo promotes cultural dialogue, inclusivity, and artistic authenticity through performances and community initiatives.

5. Why is Pedro Vaz Paulo considered influential?

Pedro Vaz Paulo’s innovation, mentorship efforts, and lasting artistic contributions have positioned him as a respected and transformative figure in modern music.

TOPIC

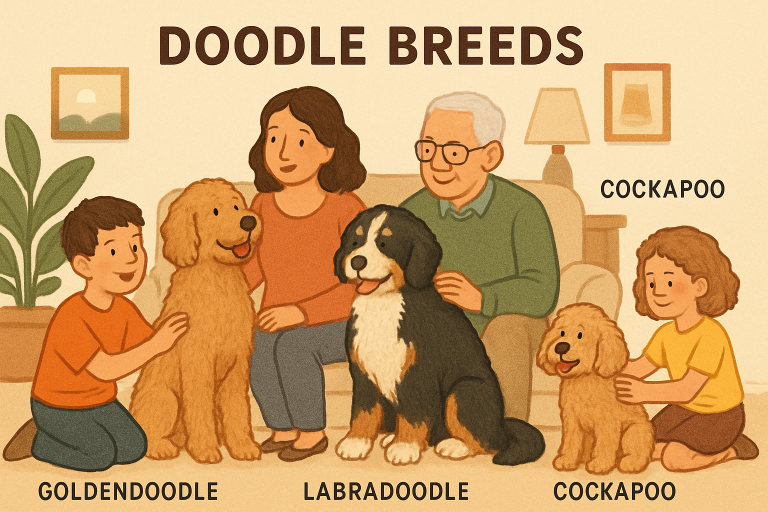

How to Choose the Perfect Doodle Dog Breed for Your Family

Bringing a Doodle dog into your home is an exciting step toward years of laughter, companionship, and love. These intelligent, affectionate crossbreeds are renowned for their appealing personalities and unique coats that come in a variety of textures and colors. Doodles have captured the hearts of dog lovers thanks to their charm, friendliness, and the hope for easier allergy management in the home. As you explore your options, including Labradoodle puppies for sale, it is crucial to understand the distinct traits and needs of each Doodle variety. Matching their energetic natures, demands, and quirks to your daily routine ensures the right fit for your lifestyle and family environment, making the experience of welcoming a new pet a joyful transition rather than a challenging adjustment.

Doodles combine the playful, low-shedding characteristics of Poodles with the distinctive qualities of other popular dog breeds. Their high intelligence often makes them highly trainable and responsive to commands, benefiting owners who enjoy teaching new tricks or engaging in dog sports. Choosing the perfect match is not just about looks, but about aligning with your family’s activity level, living space, experience with dogs, and willingness to commit to regular grooming. Before you decide, this guide walks you through understanding breed differences, lifestyle compatibility, health factors, and ethical breeding standards. Investing time in research and preparation is the key to a successful, lifelong match.

Exploring Doodle breeds opens up a wide array of fur textures, colors, temperaments, and sizes, each contributing in different ways to your home. From happy, boisterous puppies that thrive on daily walks and fetch games to mellow, cuddly dogs who love lounging beside you, Doodles offer something for almost every household. By taking the time to study these breeds and how they match your needs, you set both yourself and your new companion up for a happy partnership marked by mutual respect, love, and understanding.

Understanding Doodle Breeds

Doodle breeds are beloved for their hybrid vigor and versatility, widely cherished among families seeking hypoallergenic qualities and remarkable intelligence. Each Doodle cross can have slightly different traits depending on the parents and generation. For instance, a first-generation Goldendoodle (F1) may shed more from its Golden Retriever side, while later generations are bred for greater hypoallergenic consistency.

- Goldendoodle: A Golden Retriever and Poodle mix, these dogs are known for their upbeat, sociable personality, making them excellent companions for children. They often inherit the gentle nature of Golden Retrievers combined with the intelligence and charm of Poodles, resulting in an affectionate companion who loves interactive play, social gatherings, and water activities.

- Labradoodle: The offspring of a Labrador Retriever and a Poodle, Labradoodles often bring boundless energy, athleticism, and intelligence, making them perfect for active families. They are versatile, excelling as service animals or therapy dogs due to their keen intuition, adaptability, and outgoing temperament.

- Bernedoodle: This combination of Bernese Mountain Dog and Poodle results in loyal, affectionate pets ideal for relaxed or first-time owners. They tend to be very gentle with children and display remarkable patience with other pets and people, though their larger size often means they need more living space and occasional quiet time.

- Cockapoo: A mix between Cocker Spaniel and Poodle, Cockapoos favor smaller dwellings and are playful and loving in nature. With their adorable appearance and spirited, friendly attitude, Cockapoos are ideal for individuals or families who want a smaller companion well-suited to apartment living or urban settings.

Assessing Your Lifestyle

Finding the right Doodle starts with a realistic look at your family’s daily life. Busy, active families with time for daily exercise may appreciate energetic breeds, while quieter homes might prefer easygoing or less demanding dogs. Consider these essential elements:

- Activity Level: If morning jogs and energetic playtime are part of your schedule, breeds like Labradoodles or Goldendoodles may suit you best due to their stamina and love of activity. On the other hand, relaxed households should consider the calming presence of a Bernedoodle, which thrives in peaceful, less active settings.

- Living Space: Bigger Doodles, such as Goldendoodles and Bernedoodles, thrive with ample room to explore. Larger breeds often do best in homes with yards, while compact breeds like Cockapoos adjust comfortably to apartment living or smaller spaces, making them flexible choices for varied environments.

- Allergies: No dog breed guarantees zero allergens, but Doodles with a predominantly Poodle coat typically shed less, making them more tolerable for individuals sensitive to pet dander. Daily cleaning and grooming enhance this benefit and help manage environmental allergies for sensitive family members.

Grooming and Maintenance

Doodles generally inherit a curly or wavy coat from their Poodle lineage, which requires diligent care to avoid painful mats and tangles. These unique coats trap dirt, debris, and loose hair, increasing the importance of regular grooming. Expect to spend time on:

- Brushing your dog’s coat at least several times weekly to prevent matting and reduce the accumulation of loose hair and dirt throughout your home.

- Professional grooming every six to eight weeks to keep their coat healthy and manageable. This often includes trimming, bathing, and dealing with undercoat tangles that are difficult to maintain at home.

- Routine hygiene, including ear cleaning to prevent infections, as well as regular nail trims and dental care. Since floppy ears are common among Doodles, cleaning helps avoid bacterial growth in moist, warm ear canals.

Proper grooming not only looks good but supports your Doodle’s long-term health and comfort. Early training for grooming makes the process easier as your puppy matures, turning it into a bonding experience rather than a stressful chore.

Health Considerations

Doodles can inherit health issues common to both parent breeds, such as hip dysplasia, vision problems, heart conditions, or skin disorders. While hybrid vigor does provide some genetic diversity, it does not eliminate potential health risks. To minimize health risks, thoroughly vet breeders that require comprehensive health testing of their breeding dogs. Responsible breeders commonly screen for inherited diseases relevant to both parental lines, such as eye exams, hip and elbow evaluations, and screening for breed-specific disorders. For more on health screening protocols, consult the American Kennel Club’s guidance.

Choosing a Reputable Breeder

Your breeder selection impacts not just the health of your puppy, but your ongoing experience as a pet owner. Look for breeders who are transparent about their practices, provide documentation of health clearances, and maintain clean, loving environments for both puppies and parent dogs. Genuine breeders will willingly answer your questions, provide references, and support you throughout the adoption process. Building a relationship with your breeder provides valuable support and insights, helping you navigate the early days of puppy ownership. Take your time to research, visit multiple breeders if possible, and never feel pressured to make a quick decision.

Meeting the Puppies

Visit the breeder’s facility to observe puppies in their environment. It is important to see how puppies interact with their siblings, explore their surroundings, and respond to new people and experiences. Take your time watching how they interact with their littermates and respond to people. Look for puppies that display a stable temperament, resilience in new situations, and genuine curiosity. Ask the breeder specifics about each puppy and express your own needs and expectations to ensure a suitable match. An open dialogue increases the likelihood of finding a puppy that naturally fits into your family’s lifestyle and energy level.

Conclusion

Choosing the right Doodle for your family will involve honest self-assessment, a commitment to research, and patience in locating an ethical breeder. Prioritize thorough preparation and take the time to meet both breeders and puppies. By prioritizing health, temperament, and lifestyle compatibility, you give yourself and your new companion the best chance of a joyful, rewarding friendship for years to come. Proper planning and a thoughtful adoption process make the transition to Doodle dog ownership a positive experience for every member of your household. Ultimately, taking these thoughtful steps ensures years of happiness, adventure, and heartfelt memories with your newest family member.

-

TOPIC1 year ago

TOPIC1 year ago7 Expert Tips For Choosing The Best Basement Renovation Companies

-

TOPIC1 year ago

TOPIC1 year agoWhy Large Waterproof Outdoor Rugs Are Essential for All Outdoor Spaces

-

TOPIC8 months ago

TOPIC8 months agoWhy Greece Katz Martian Has Everyone Talking in 2025

-

BUSINESS9 months ago

BUSINESS9 months agoTop 5 Features of Sowix Online That Every User Should Know About

-

TOPIC9 months ago

TOPIC9 months agoTop Features of BetterThisWorld .com You Need to Know About

-

FASHION1 year ago

FASHION1 year agoHow to Layer Your White Dress for Cold Weather?

-

FINANCE1 year ago

FINANCE1 year agoHow TraceLoans Can Simplify Your Finances

-

BIOGRAPHY1 year ago

BIOGRAPHY1 year agoFrom Reality Star to Business Mogul: Prince Narula Digital PayPal